Prepare

Important, Please Read:

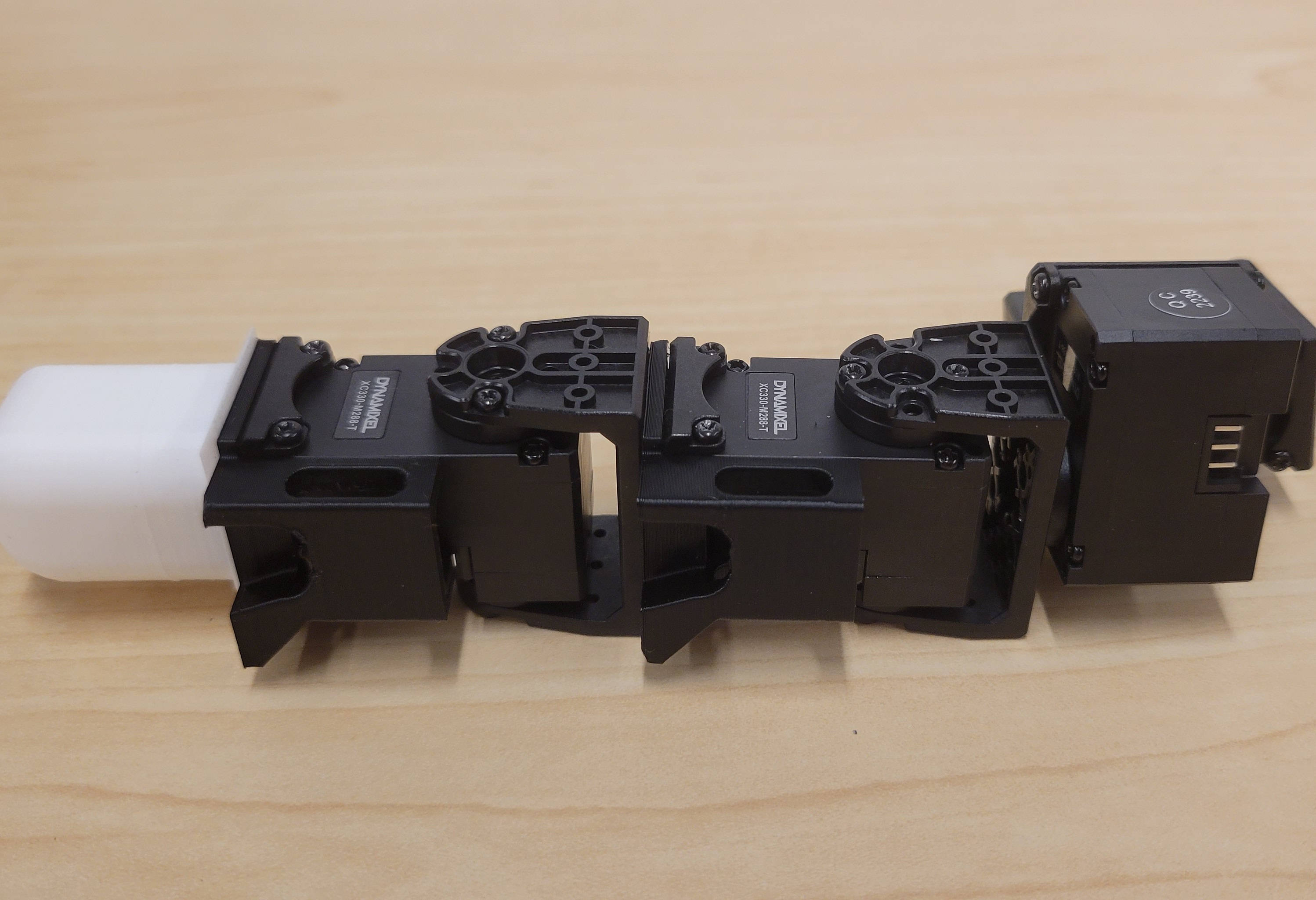

The dots and dashes I've outlined on the motor horn indicate the Home position for the Dynamixels. When the LEAP Hand receives the 180-degree home command at power-up, the Dynamixels will automatically move to this position. Most Dynamixels are shipped already oriented in this home position.

For proper assembly, ensure the motor horns are in this home position when attaching to the joints. When the hand moves to its home pose, it should perfectly replicate the CAD model's position.

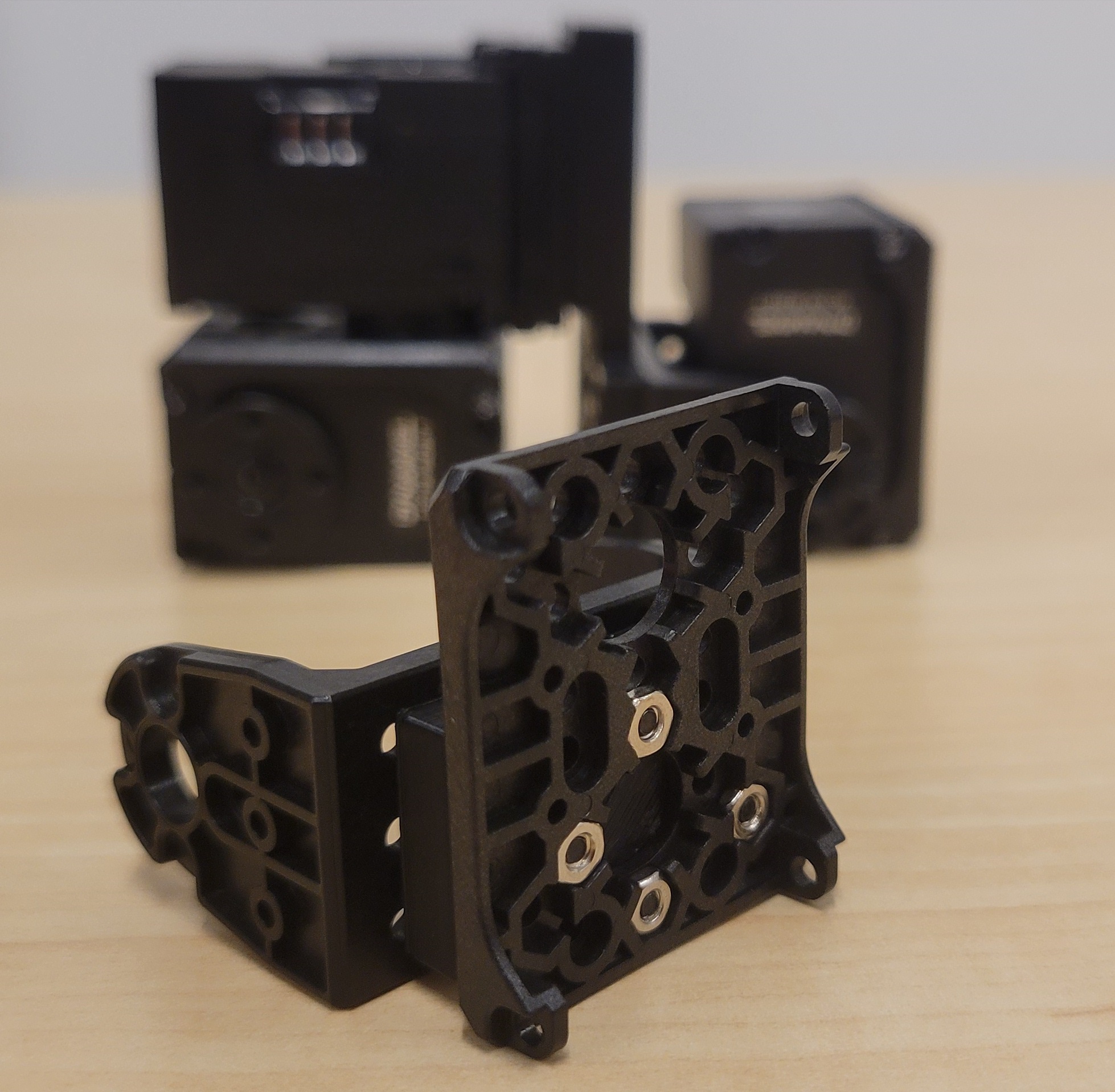

There are three distinct types of screws used in assembly:

TAP Screws (Left): These Phillips head screws have serrated edges and come included with the Dynamixel brackets

Standard Dynamixel M2x4mm (Middle): These are regular, non-TAP screws supplied by Dynamixel

Hex Head Screws (Right): These are standard hex-head screws

Screw sizing: The first number (M2 or M3) indicates the screw diameter in millimeters, while the second number specifies the length (e.g., 8mm, 10mm).